Precision CNC Machining Capabilities and Services

We have the technical experience, quality and the high capacity, multi-tasking CNC machines that offer the solutions, your complex component requires. We specialize in high volume production. Through efficient automation and proven processes, we consistently deliver quality parts in the high quantities necessary for our customers.

Our manufacturing facility is a climate controlled 25,600 sq. ft. tilt-up concrete building.

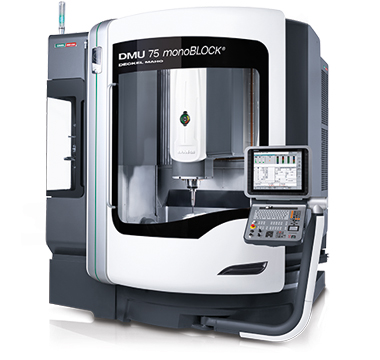

DMU 75 Monoblock 5 Axis Milling

5 Axis CNC Milling:

(1) DMG MORI DMU 75 monoBlock – Max. X-axis 29.5in, Max. Y-axis travel 25.6in, Max Z-axis travel 22in, table diameter 25.6in

Horizontal 4 Axis CNC Milling:

(1) Mazak Nexus 6000-II Horizontal Machining center – 32″ x 32″ x 32″ travels

(2) Toyoda HSP550 Horizontal Machining Centers – 32″ x 32″ x 32″ travels

(3) Toyoda FA400 Horizontal Machining Centers – 20″ x 20″ x 20″ travels (1) DMG MORI NHX5000 Horizontal Machining Center – 28″ x 28″ x 34″ travels w/ 5 pallet pool

Vertical 3 Axis CNC Milling:

(2) DMG MORI CMX 1100 V Vertical Machining Center – 43″ x 22″ x 20″ travels

(1) Makino KE 55 Vertical Machining Center – 22″ x 12″ x 12″ travels

Precision CNC Turning:

(1) DMG Mori-Seiki Lathe NLX2500SY with 4″ diameter bar capacity

(1) DMG Mori-Seiki Lathe NLX2500SY/1250 with 4″ diameter bar capacity

(3) DMG Mori-Seiki Lathe NLX2500SY with 3″ diameter bar capacity

(1) Esco D-2 Flex-speed Swiss screw machine

(1) Royal Master Centerless Grinder with bowl feeder

Software:

• CAD data from Pro-E, Solidworks, AutoCAD, Ideas, UGS, IGES, STEP, ACIS, Parasolid, DXF

• Calypso CMM inspection software

• ERP Shop Management Software

Finishing In-House:

• Vibratory Tumblers

• Glass Bead Blasting

Miscellaneous:

• Marvel CNC Production Band Saw

• Taumel Bench-top Model T-251

• Vacum Pfeiffer Adixen ASM 340WET

• Fully equipped Tool Room

• Various Production Support Equipment

Outsourced Services:

We have tested relationships with numerous finishing companies to save our customer’s time and money through the convenience and quality of an all in one manufacturing location.